Brushless DC blowers are rapidly gaining popularity across various industries for their ability to provide more reliable, efficient, and longer-lasting performance compared to traditional blower systems. These blowers, powered by brushless DC motors, combine advanced engineering with practical applications in systems requiring controlled airflow. This article Caforre explores the underlying technology and important considerations when selecting brushless DC blowers for specific use cases.

The Technology Behind Brushless DC Blowers

Brushless DC blowers are powered by brushless DC motors, a cutting-edge alternative to traditional brushed motors. To understand the performance advantages of these blowers, it is essential to look into the technology that drives them. Unlike traditional motors that rely on brushes and commutators to transfer electricity to the rotor, brushless DC blower motors use electronic controllers to switch the current in the windings, creating a rotating magnetic field. This rotating field interacts with permanent magnets on the rotor, producing torque and enabling motion.

This brushless design eliminates the friction between brushes and commutators, which traditionally causes heat buildup and wear. The absence of these components means that the system is much more efficient, with reduced energy losses, longer motor life, and less maintenance. Furthermore, the electronic controller allows for more precise speed control and smoother operation, making brushless DC blowers ideal for applications that require highly consistent airflow or variable-speed operation.

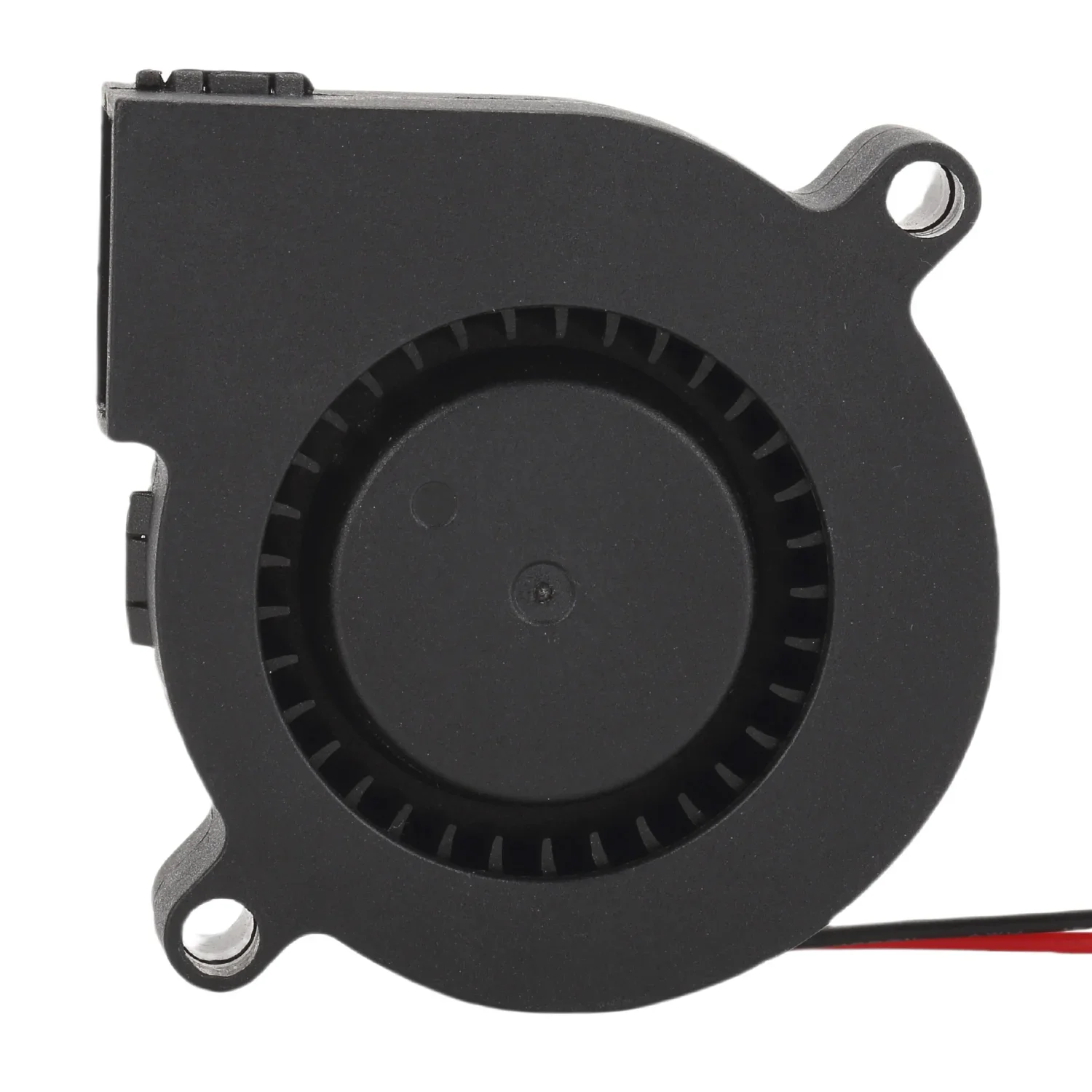

In terms of construction, a brushless DC blower typically consists of a rotor (the rotating part), a stator (the stationary part with coils), and a controller that manages the current distribution to the stator coils. The absence of mechanical brushes in the system allows the motor to achieve better performance with reduced maintenance needs, which are particularly important for applications that require long operational lifespans or high reliability.

Technical Considerations When Choosing a Brushless DC Blower

Choosing the right brushless DC blower for a given application involves several technical factors. The following points should be considered to ensure the blower meets performance requirements while operating efficiently and reliably.

Airflow Requirements

The most critical factor to consider when selecting a brushless DC blower is the required airflow. Different applications demand different airflow levels, typically measured in cubic feet per minute (CFM) or liters per second (L/s). For instance, cooling systems in electronics require precise airflow control to prevent overheating, while HVAC systems require larger volumes of air to maintain comfortable indoor climates. Choosing a blower that can deliver the necessary airflow without overworking the motor is crucial for ensuring both system efficiency and longevity. An oversized blower can lead to unnecessary energy consumption, while an undersized blower may fail to meet the system's needs.

Voltage and Power Supply Compatibility

Brushless DC blowers operate at different voltage levels, ranging from 12V to 48V or even higher, depending on the application. It's essential to choose a blower that is compatible with the available power supply. For example, automotive applications typically require 12V or 24V systems, while industrial applications may use 48V systems for more powerful blowers. Choosing the correct voltage also ensures that the blower operates at its optimal performance, avoiding overloading or underperformance due to mismatched power sources.

Size and Form Factor

Space constraints are often a significant consideration when selecting a blower. Brushless DC blowers are known for their compact size, making them suitable for applications where space is limited. However, it's important to carefully assess the space available for the blower in the system, as well as any potential integration challenges. The form factor should also match the required mounting options, airflow direction, and other physical constraints of the application. A blower that is too large or has the wrong form factor could complicate the integration process and affect overall system performance.

Noise Level

In noise-sensitive environments, the operational noise of a blower is a critical factor to consider. Although brushless DC blowers are quieter than traditional brushed motors, noise levels can still vary depending on the model and design. Applications in medical devices, offices, or home appliances often require very low noise levels, so it's essential to check the blower's noise specifications before making a decision.

Control Options

The level of control over the blower is also important. Some brushless DC blowers come with integrated controllers that allow for variable speed operation, enabling more precise adjustments to airflow. In more advanced systems, additional features such as temperature sensors or programmable settings can further enhance the blower's functionality, enabling it to adapt to changing conditions and optimize performance over time.

Brushless DC blowers have become an essential component in modern engineering and technology due to their efficiency, longevity, and versatility. With their ability to provide precise airflow control, reduced noise levels, and superior energy efficiency, they have found widespread use across industries like HVAC, electronics, medical devices, automotive, and industrial ventilation. When choosing the right blower, it is crucial to consider factors such as airflow requirements, power compatibility, size, and noise levels to ensure optimal performance and integration into the system. As industries continue to prioritize energy efficiency and sustainability, brushless DC blowers are expected to remain at the forefront of innovation, offering both performance and cost-effectiveness in a variety of demanding applications.

https://www.szcaforre.com/Unlocking-Efficiency-and-Precision-with-Brushless-DC-Blowers.html

https://www.szcaforre.com/DC-Blowers

www.szcaforre.com

Shenzhen Caforre Technology